3D Printing with Selecting Laser Melting

EP-M250 Metal 3D printing

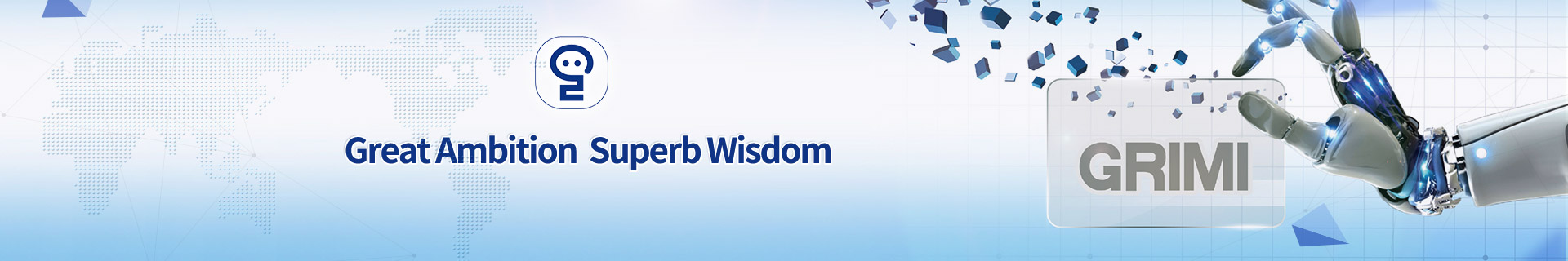

Model samples printed by EP-M250

SLM(Selective Laser Melting)is a kind of technology which under the control of computer program to use a high-energy-density laser to scan, then selective melting pre-laid metal powder layers to combine with matrix metallurgy, then continuously paving and scanning layer by layer, finally completing the three-dimensional metal parts.

The materials are stainless steel, copper alloy, titanium alloy, cobalt-chromium alloy, nickel-chromium alloy etc.

Features

1、It is suitable for single and small batch production, and can directly produce metal products, saving the cost of mould and the time of making a new mould.

2、It is suitable for casting the workpiece with complex structure, especially for complex internal structures (such as cavity), complex workpieces that cannot be manufactured by conventional methods, or for the conditions where material costs are high and waste of material because of using the subtractive materials process.

|

product model |

EP-M250 |

|

Model building size(mm) |

250*250*300 |

|

Laser |

Resonant Fiber Laser200w/400 |

|

Scanning system |

High-precision scanning galvanometer |

|

control software |

Eplus 3D printing software |

|

height of print layer |

0.02mm~0.1mm |

|

ambient temperature |

working temperature is15~30℃

|

|

gas supply |

Ar/N2 protect |

|

scanning speed |

8m/s |

|

Power supply and power consumption |

380V 6KW |

|

Appearance dimension (mm) |

2500m*1000*2100 |

SLM technology has mature applications in the fields of metal mold manufacturing, lightweight metal parts manufacturing, porous structure manufacturing and medical implants.

Parts printed by metal 3D printer

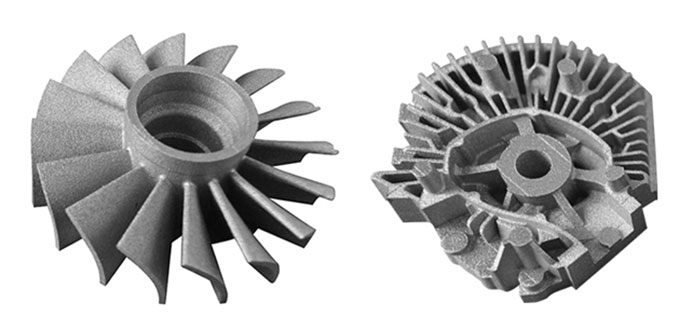

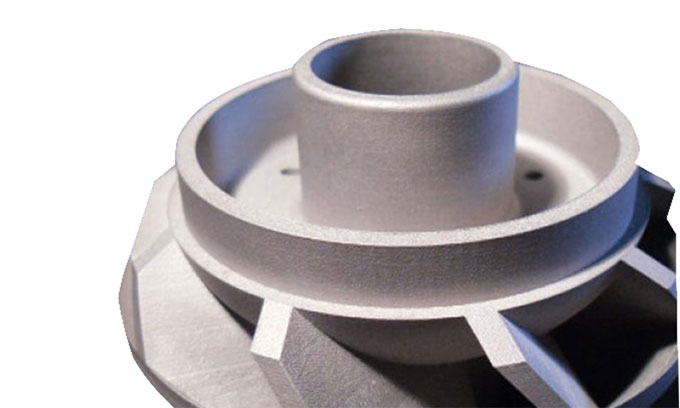

Impellers printed by metal 3D printer

Parts assembled from impellers printed by metal 3D printer