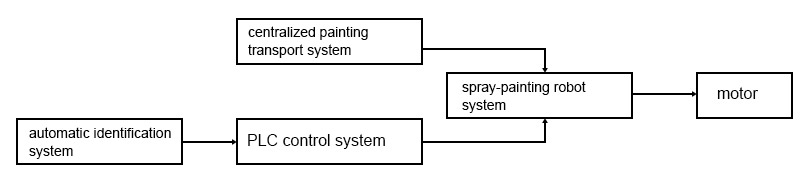

Fully Automatic Spray-Painting Robot Production Line

Fully automatic spray-painting robot production line consists of explosion-proof painting robot, centralized painting transport system, PLC control system and automatic identification system. Firstly, the automatic identification system recognizes the workpiece and read the MES spraying requirements, then the centralized paint transport system automatically changes the color for painting. Finally, the PLC control system controls the spraying robot to retrieve the corresponding program for automatic painting. The production line runs fully automatically, with high production efficiency, good spraying quality, and saving material costs. It can be widely used in automobiles, engines, mechanical parts, home appliances, furniture, sanitary ware, aerospace and other fields.

Automatic painting process

The production line has the following features:

1、It can replace the workforce working in the high-risk environment ;

2、It improves the spraying production efficiency and brings stable spraying quality;

3、 It improves the utilization of paint and reduces emissions.

Centralized painting transport system

Pxplosion-proof painting robot