Solution for Digital Sugar Factory

1, Overview

GRIMI relied on years of accumulated sugar high-end equipment and factory software implementation and development experience, based on the relevant data of sugar production process, to help users establish the integrated system of PCS, MES, and ERP. It covers the sugarcane cutting and dispatching optimization system, the digital cane field, the digital power workshop, the digital press shop, the digital refining workshop, the fully automatic unmanned packing workshop, the intelligent production process of warehousing and the product traceability, etc. It can realized the automatic control and information management for a digital sugar mill production mode, which can achieve the following economic indicators:

1). The sugar production rate is increased by 0.5%;

2). Energy saving is more than 20%;

3). The operator in each production line can be reduced to 100 people;

4). Production costs are reduced by 10-15%.

The solution solves the existing problems of “automated islands” and “management information islands” in sugar factories, helping sugar factories to achieve fine management, balanced production, energy saving, improving product quality, increasing production, reducing emissions, reducing costs, and greatly improving the level of management, enhancing the market competitiveness, and maximize profits. Through the demonstration driving effect, it will lead the development of China's sugar industry in the next decade.

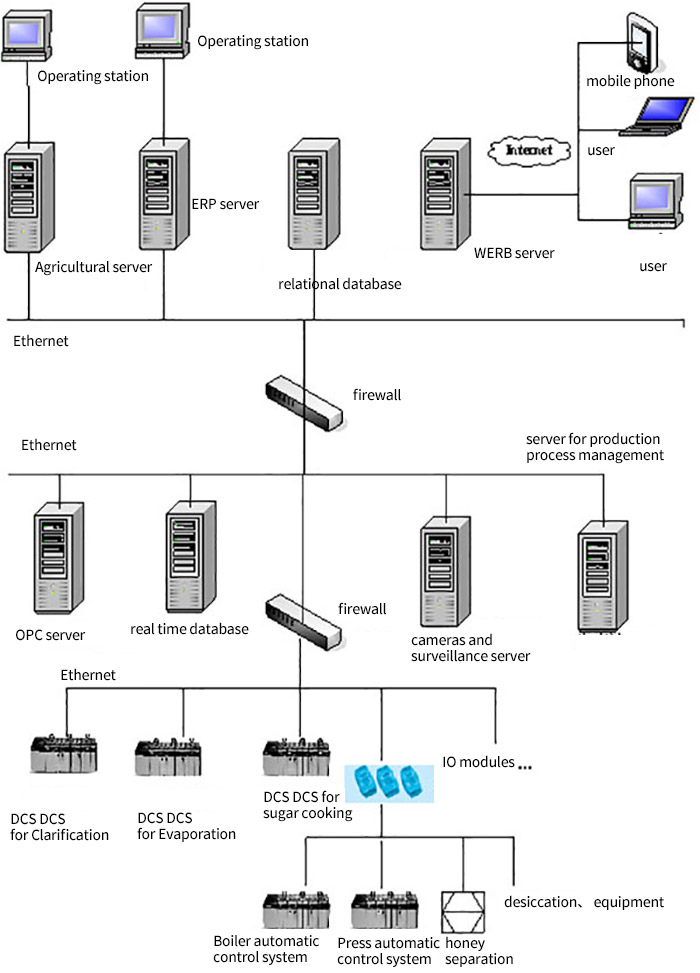

2, System Architecture

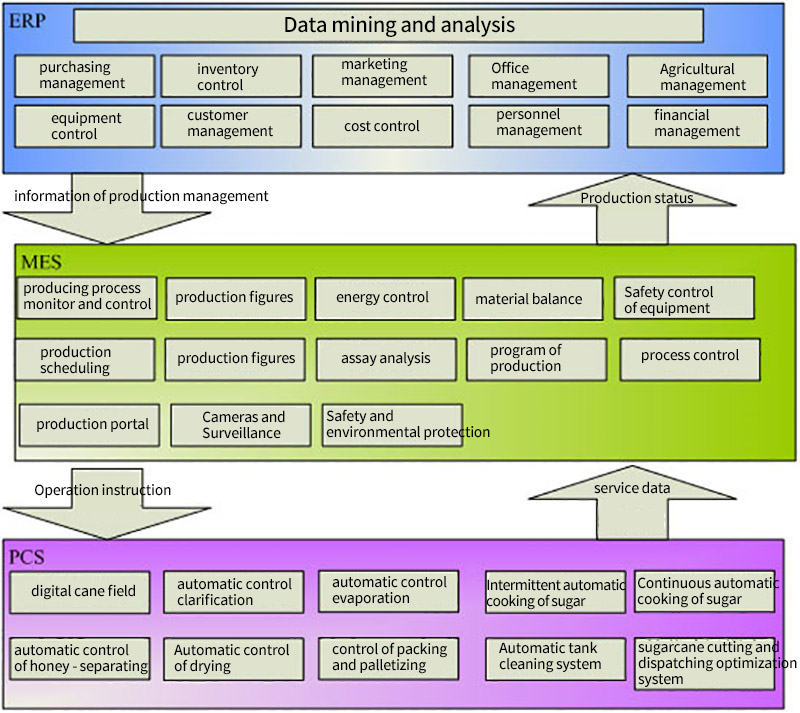

The system is divided into three layers: ERP/MES/PCS. MES is the middle layer which provides data resources and interfaces to the upper layer ERP, and flexibly expand and link the under layer PCS, completes the automatic control and management of production process, business management information and other purpose.

System architecture diagram

1) PCS layer

It analyzes, optimizes, and establishes control models for key processes in the shop by collecting various parameters of the sugar process, adopts DCS process control technology and high-efficiency automation equipment such as sugarcane cutting and dispatching optimization system, cane field digitization, automatic control clarification, automatic control evaporation, intermittent automatic sugar control, continuous automatic sugar control, and fully automated control of labor-intensive sections such as clear cans and sugar candy packaging.

2) MES layer

It was established a centralized control center in MES layer to collect and exchange information on the automatic control system of the workshop, and establish an interactive control model between each section. Through interactive control, it can effectively deal with abnormal situations automatically, reduce manual participation, avoid isolated control of each process, and realize linkage control of each section. It Integrates the information of each process control subsystem and the information of the production management system to realize the integration of management and control of the production process. It mainly achieves the balance of materials, water, energy and auxiliary materials, optimization of process parameters, production safety and stable and reliable quality.

3) ERP layer

It can realize the informationization of enterprise management, implement sales management, procurement management, inventory management, office management, equipment management, personnel management, agricultural management, financial management, data analysis and mining, etc., to achieve data integration and sharing among various systems and fine management of the enterprise.

3, Network Structure Design

GRIMI adheres to advanced hierarchical design principles in the overall design of the network structure, and vertically and horizontally divides the network system according to the organization management mode and geographical distribution, thereby decomposing the complex problems into multiple levels and relatively simple.

The main advantages of hierarchical network design are that it greatly simplifies the management of the network and facilitates monitoring and management of the entire network. At the same time, it can optimize the performance of each layer of network and application systems, and promote the collaboration and process development of various services. Therefore, according to the organizational management structure of the enterprise and the geographical distribution of each node organization, the network system is divided into three network layers in the vertical direction: PCS, MES, and ERP .